What To Do If the Hema FG Control Doesn’t Turn Blue

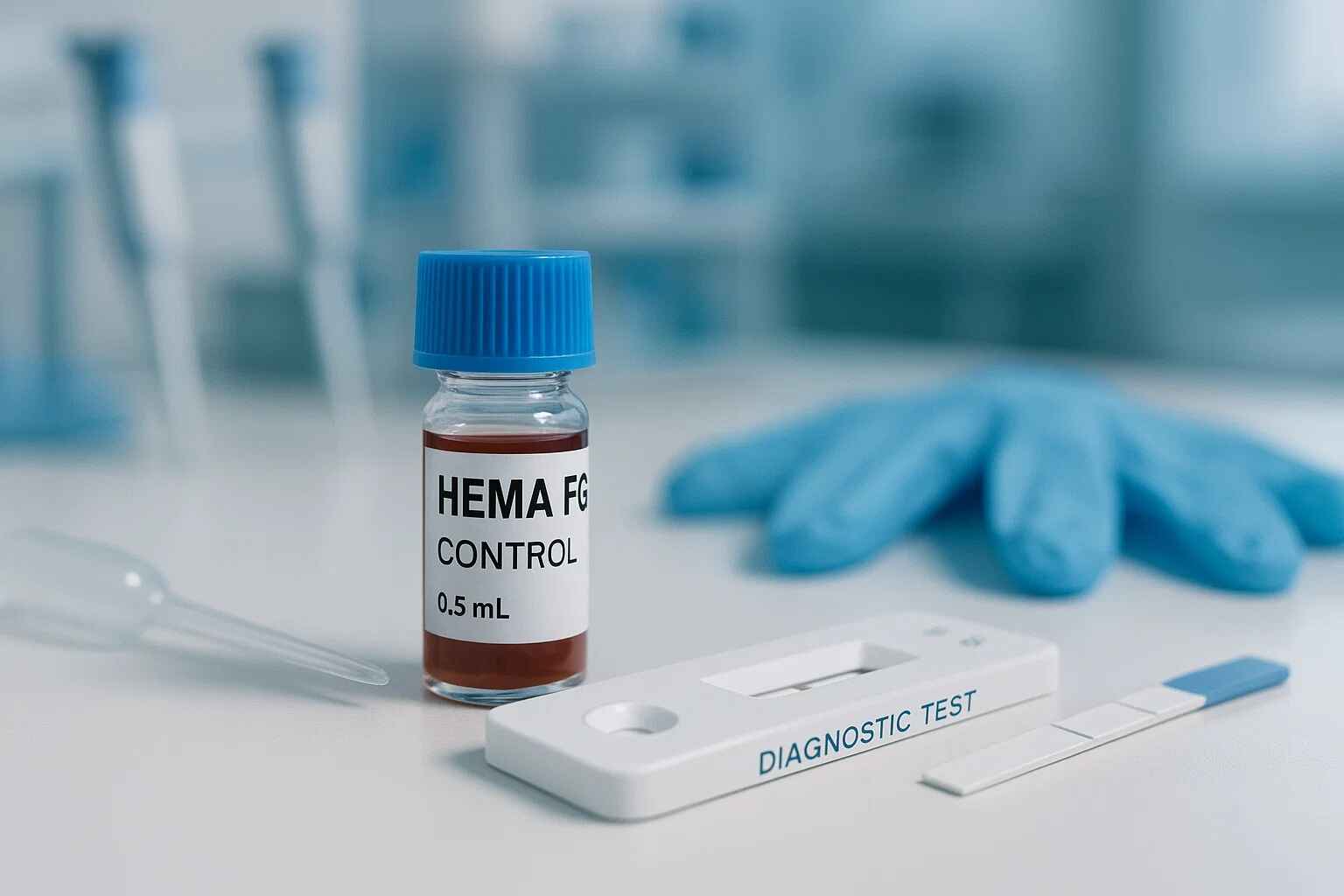

When performing diagnostic tests, accuracy is crucial, and issues like an unresponsive Hema FG control can create challenges. If your Hema FG control doesn’t turn blue, it’s important to figure out the issue quickly to ensure your results are both reliable and precise. This article dives deep into the common reasons behind this problem and provides actionable steps to resolve it. We’ll also explore preventive measures and frequently asked questions to guide you toward better troubleshooting outcomes.

Why Hema FG Control Turning Blue Matters

The color change in Hema FG controls, specifically turning blue, is a key indicator of the test’s functionality. This reaction confirms that the control solution is working as intended. When it doesn’t turn blue, it can signal a procedural issue, an environmental factor, or even a product malfunction. Without the blue indicator, you cannot confirm the validity of your test, which might lead to questionable results.

Key reasons the blue color matters:

- Validation of the control’s functionality.

- Affirmation of proper test procedure.

- Ensuring credible diagnostic outcomes.

If the control doesn’t turn blue, it’s not just a minor inconvenience; it directly affects the accuracy of your testing process, which can impact treatment plans or research findings.

Common Reasons Why Hema FG Control Doesn’t Turn Blue

1. Incorrect Storage Conditions

Hema FG controls are sensitive to their environment. Storage plays a significant role in maintaining their effectiveness. If they’re exposed to improper conditions, their chemical properties can degrade, preventing them from turning blue.

Storage factors that might affect performance:

- Temperature: Controls exposed to extreme heat or cold may lose functionality.

- Humidity: High moisture levels can contaminate controls.

- Light Exposure: Prolonged exposure to direct sunlight may alter the solution’s efficacy.

Solution: Always store your Hema FG control between the recommended temperature range stated on the packaging and in a dry, shaded area.

2. Expired or Contaminated Controls

Using controls past their expiration date or those that have been contaminated will compromise test results. Always check the packaging for the expiration date and inspect for any visible contamination.

- Expired controls lose chemical stability.

- Contaminated solutions may show inconsistent results.

Solution: Only use unexpired controls and replace any compromised ones immediately to ensure consistent performance.

3. Missteps in Test Procedure

Even with the most reliable control solutions, procedural errors may disrupt the color change process. Skipping steps, using incorrect materials, or mismeasuring solutions can lead to incomplete reactions.

Common mistakes:

- Skipping the activation step.

- Adding control liquid in incorrect amounts.

- Using incompatible test strips or tools.

Solution: Reference your test guide and follow each step precisely. Spend extra time measuring and applying the control solution correctly.

4. Product Malfunctions or Manufacturing Issues

Although rare, product defects or manufacturing inconsistencies can sometimes cause Hema FG controls to malfunction. This could include issues like an incomplete formulation or broken containers.

Solution: If you suspect a defective product, contact the manufacturer for support or request a replacement. Retain your proof of purchase for a quicker resolution process.

How to Troubleshoot the Issue

- Recheck the Procedure: Review your testing steps to ensure accuracy.

- Inspect the Control Solution: Look for contamination or expiration.

- Test Environmental Factors: Ensure the control is stored correctly and within temperature guidelines.

- Trial with a New Solution: If all else fails, consider using a fresh Hema FG control to eliminate possible issues with an old batch.

Preventive Measures To Ensure Consistent Performance

Prevention is always better than troubleshooting, and there are several ways to minimize the risk of your Hema FG control not turning blue.

Best practices for prevention:

- Store Properly: Maintain recommended storage temperatures and ensure the area is dry and away from direct light.

- Use Fresh Solutions: Avoid using expired controls or ones that have been exposed to contaminants.

- Follow Guidelines: Always adhere to the procedural instructions for your specific test.

- Conduct Routine Checks: Periodically verify the integrity of your controls, ensuring no visible damages or signs of inefficacy.

By taking these steps, you’ll reduce the likelihood of disruptions in your testing process.

When to Contact the Manufacturer

If your Hema FG control repeatedly fails to turn blue despite following all protocols, it may be time to involve the manufacturer.

- Explain the issue in detail, including any troubleshooting steps you’ve already taken.

- Provide batch numbers or other identifiers.

- Request a replacement or inquire about a refund, depending on your situation.

Many manufacturers have dedicated support lines for resolving such issues promptly.

FAQs

What can cause Hema FG controls to expire before their expiration date?

Improper storage, such as exposure to extreme temperatures or light, can degrade the chemical components in Hema FG controls faster than expected. Always store them in a controlled environment.

Can I still use a control that doesn’t turn blue?

No, a control that doesn’t turn blue is unreliable and cannot confirm the accuracy of your diagnostic test. Always replace unresponsive controls.

How long does it take for the Hema FG control to turn blue?

The color change should occur within the time specified in the instructions, typically a few minutes. Delays might indicate an issue with the test procedure or the control solution.

Are there alternative brands if my Hema FG control keeps failing?

Yes, there are other reliable diagnostic control solutions available. Consult with your supplier or manufacturer for recommendations.

Can environmental conditions alone prevent the control from turning blue?

Yes, environmental factors like heat, sunlight, or moisture can alter the effectiveness of Hema FG controls and prevent the color change reaction.

Should I refrigerate Hema FG controls to extend their shelf life?

Refrigeration is not always suitable and can sometimes damage the solution. Follow the packaging storage guidelines instead of improvising.

How do I know if my testing procedure is incorrect?

Review the manufacturer’s instructions closely or consult a professional to identify potential missteps in your procedure.

Can faulty Hema FG controls affect patient outcomes?

Yes, an unresponsive control can lead to inaccurate test results, potentially impacting treatment planning or clinical decisions.

Conclusion

A reliable Hema FG control is essential for accurate diagnostic testing, with the blue indicator serving as a key confirmation of successful results. When your Hema FG control doesn’t turn blue, it’s important to identify and resolve the issue quickly to ensure testing integrity. From storage conditions and expiration to procedural errors and manufacturing defects, there are several factors to consider.

By following proper storage guidelines, using fresh controls, and adhering to test procedures, you can reduce the chances of encountering this issue. If problems persist, don’t hesitate to contact the manufacturer for support or explore alternative solutions. By being proactive and thorough, you can ensure dependable testing outcomes every time.

The Springfield 1816 Lock: A Deep Dive into Its Significance and Legacy